Quarry Mapping, Stockpile Surveying and Mine Management Using Mobile LiDAR Scanning

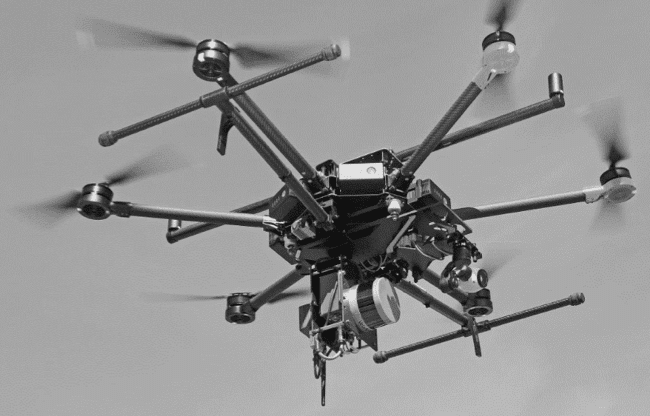

Quarry mapping, stockpile surveying, volume extraction, and open-pit mine planning have typically been performed using ground-based survey sensors, an approach that is time-consuming and often requires “boots on the ground” to carry equipment. This is done while walking across steep slopes with loose gravel and operating under unsafe conditions e.g. high cliffs. When it comes to optimizing the management of your quarry mapping or pit, accurate geospatial data is key. Today, no tool comes close to providing such data as efficiently, or as safely, as LiDAR drones. Geodetics’ turn-key Geo-MMS LiDAR Drone mapping solution shown below, offers a new paradigm for data collection in quarry mapping & pit operations. It can significantly save time on data collection and greatly reduce the risks of the survey crew.

Figure 1: Geodetics’ Turn-Key System Equipped with Geo-MMS LiDAR

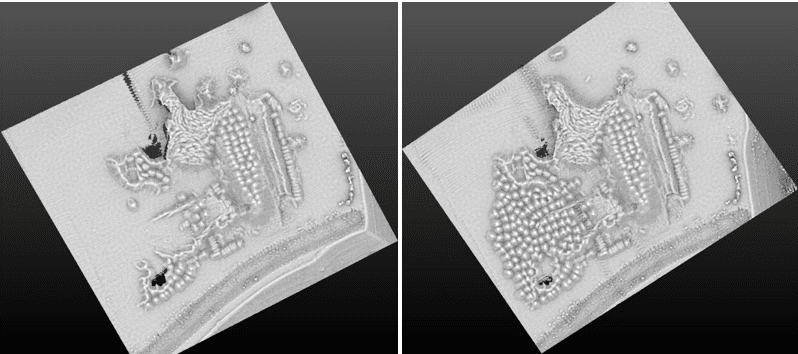

Geo-MMS LiDAR Drone was used twice to survey a quarry area with a three-day separation between the surveys. Figure 2 shows the LiDAR point clouds of the area from both surveys. As shown below, new stock material was added to the field between surveys and the goal was to estimate the volume of the new stock.

Figure 2: Geo-MMS LiDAR Drone Quarry Mapping in Two Different Days

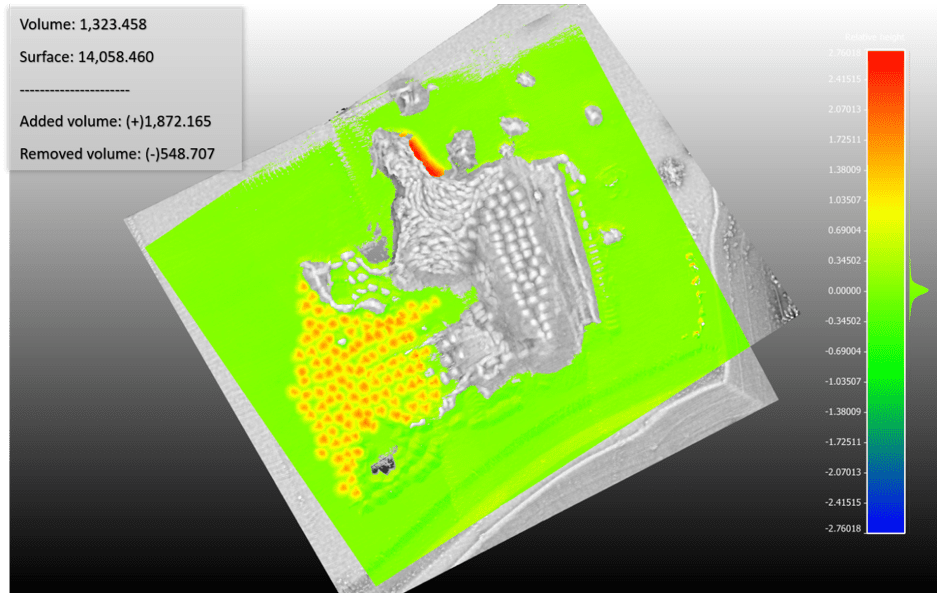

In order to accomplish this, two Geo-MMS LiDAR Drone generated geo-referenced point clouds were utilized. As seen in Figure 3 (below), change detection between two georeferenced LiDAR point clouds enabled us to determine the volume difference between the two surfaces quickly.

Figure 3- Volume Extraction between Two Datasets

Utilizing Geodetics Geo-MMS LiDAR Drone for a single automated flight can collect timely, georeferenced imagery that is quickly transformed into a precise 3D copy of a quarry site or pit. This technology can be used to calculate volumes, perform site surveys, design road layouts and much more. Geodetics Geo Mobile Mapping System LiDAR Drone can be customized for each job. High quality and priced right request more info below.